Hytech PLC – HMI training kits are ergonomically designed kits which are equipped with automation modules as well as PLC and Field Input / output modules which make them convenient to operate as well as program.

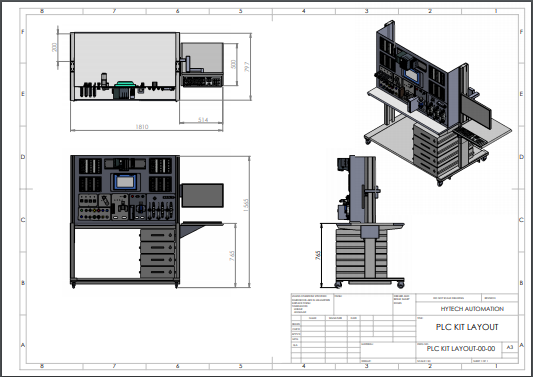

There are two models, one of which is table mounted and the other one is floor mounted.

The floor mounted model (Model: PH Advance) is equipped with a workstation mounted on the kit which is connected to PLC and HMI through a switch.

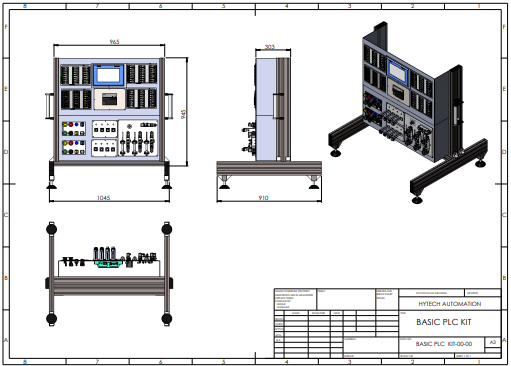

The table top model (Model: PH Basic) does not come with a workstation. It is provided with a licensed software of a PLC / HMI that is used in the system which can be installed in a workstation with relevant specifications.

Any PLC / HMI can be provided with Hytech PLC – HMI trainer kits. Indigenously designed PLC and Field Input – Output modules are equipped with a 25 pin connector which can be very easily connected with any PLC / HMI.

The ‘Hytech PLC – HMI’ training kits are designed to provide hands on experience to participants on integration of PLC – HMI and workstation with industrial automation components such as:

INDUSTRIAL AUTOMATION MODULES:

- Automation Module : Servo Motor Module

- Automation Module : AC Motor and External Encoder Module

- Automation Module : Stepper Motor Module

- Automation Module : Switchgear Module

- Automation Module : Pneumatic Solenoid Module with Pneumatic Cylinders

- Automation Module (Analog Input) : Pneumatic Digital Pressure Switch (with Analog o/p) with Pneumatic Cylinder (For Analog Applications)

- Automation Module (Analog Output) : Variable Frequency Drive (VFD) with AC Motor (For Analog Applications)

Key Features of Hytech PLC and HMI Training Kit:

- Indigenously designed PLC Input and output modules with a short circuit protection which completely isolates PLC and provides necessary freedom to participants to carry out PLC connections with ease.

- Indigenously designed Field Input and output modules which makes it easier for participants to connect the automation modules as well as to carry out ladder programming.

- Ergonomically designed kit which makes it easier for three students to work at a time.

- Use of all industrial components gives participants hands n experience on industrial automation as well as PLC – HMI integration

Electrical wiring is done with necessary test points to provide basic understanding to participants about electrical panel maintenance as well as troubleshooting.