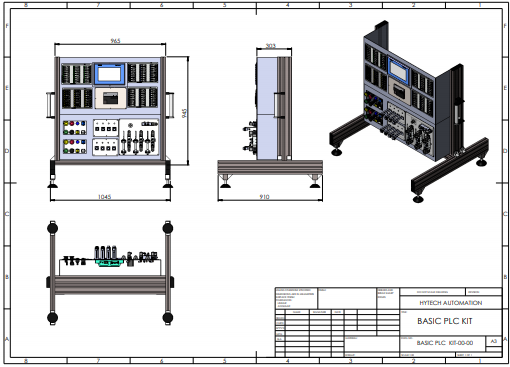

PH Basic is a table mounted model of Hytech PLC and HMI training Kit.

This model is generally suitable for entry level PLCs such as Siemens S7 200 Smart or Mitsubishi FX Series. HMI provided with the kit is again an entry level HMI such as Siemens KTP 700 Basic or Mitsubishi GS Series.

PH Basic model does not come with a workstation but all necessary licenses / softwares are provided along with the kit. Basic kit can be easily lifted and taken to a classroom to conduct demonstrations.

Although, Bill of material of any particular training kit changes as per the models of PLC and HMI as per customer’s requirement along with automation modules, following items / components are provided along with each PH Advance model:

- Field Input Module

- Field Output Module

- PLC Input Module

- PLC Output Module

- 5 / 8 port switch

Following Automation modules are supplied along with the PH Advance model irrespective of the make and model of PLC / HMI. These automation modules are ergonomically mounted to make sure that participants can carry out the programming / execution easily.

- Sensor Module

- Switchgear Module

- Pneumatic Solenoid Module with Pneumatic Cylinders

Following Miscellaneous components are also included along with the kit to make operation efficient:

- Profinet Cable (Cat 6) minimum 1 meter, Qty: 02

- Hand Slide (3/2) Pneumatic Valve for quick exhaust

- Pneumatic Junction box (Minimum 4 ports)

Customers can select from following mentioned automation modules which can either be mounted on the kit or can be provided individually which can be integrated with the kit:

- Automation Module (Analog Input) : Pneumatic Digital Pressure Switch (with Analog o/p) with Pneumatic Cylinder (For Analog Applications)

- Automation Module (Analog Output) : Variable Frequency Drive (VFD) with AC Motor (For Analog Applications)

Key Features of Hytech PLC and HMI Training Kit (PH Basic Model):

- Indigenously designed PLC Input and output modules with a short circuit protection which completely isolates PLC and provides necessary freedom to participants to carry out PLC connections with ease.

- Table mounted kit with ergonomically designed holding arrangement for easy pick up / placement.

- Complete structure in powder coated mild steel to provide required rigidity.

- Provision of Ethernet switch which enables other workstations to be connected to PLC-HMI kit with ease.

- Indigenously designed Field Input and output modules which makes it easier for participants to connect the automation modules as well as to carry out ladder programming.

- Ergonomically designed kit which makes it easier for three students to work at a time.

- Use of all industrial components gives participants hands n experience on industrial automation as well as PLC – HMI integration

- Electrical wiring is done with necessary test points to provide basic understanding to participants about electrical panel maintenance as well as troubleshooting.