Hytech Modular Production Systems (MPS) are designed to provide hands on experience to participants on latest industrial automation practices as well as technology.

All Hytech MPS stations are equipped with PLC and SCADA Connectivity. PLC used is generally Siemens S7 1200 series PLC unless customer is looking for a specific model / make of PLC.

Few of the very important features of Hytech MPS are as follows:

- Hytech MPS is directly connected to SCADA (MPS CCU) which provides training on latest SCADA technology. Various parameters (Chosen by participants) can be displayed on the SCADA screen. Process can be optimized as well as changed as per the requirement.

- Each station can be dynamically simulated in a 3D simulation software which can simulate the entire process in 3D. Participants can also design the various processes in a software which can be executed on MPS hardware.

- Process is completely flexible. Participants can decide the flow of process as well as the sequence of operations. Participants can design the entire SCADA / Operation screen which makes this system an actual ‘Flexible Manufacturing System’.

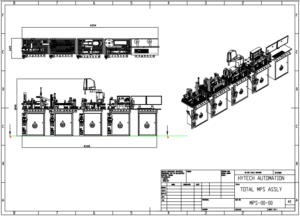

MPS 1 : Material Based Sorting with Height Sensing Application

MPS 2 : Color Based Sorting with Drilling Application

MPS 3 : Weight Based sorting with 4 axes Industrial SCARA (3 KG Payload)

MPS 4 : 4 Station rotary indexing application with automatic storage system (8 station)

MPS CCU : Central Control Unit with SCADA and OPC UA connectivity with remote operation panel

Modular Production System Overview

Modular Production System Operation

What exactly this system provides:

- Hands on experience on latest industrial PLC (Siemens / Mitsubishi / Rockwell). Can also be used for PLC training courses

- Hands on experience on latest industrial HMI (Siemens / Mitsubishi / Rockwell). Can also be used for HMI training courses

- Hands on experience on latest industrial SCADA (Siemens / Mitsubishi / Rockwell). Can also be used for SCADA training courses

- Training on 4 Axes industrial SCARA (Mitsubishi)

- Operation of SCARA through PLC and SCADA

- Pick and place operation of SCARA in individual mode as well as integration mode

- Factory design and simulation in 3D software (IGES files)

- Complete process simulation through OPC UA connectivity

- Exposure to various industrial automation products such as Guided Cylinder, Rotary vane motors, stepper motors, color sensors, load cells, Rod less cylinders etc.

- Components selection based on applications.

- Operation of stepper motor / AC motor with PLC and SCADA

- PLC operation through SCADA