Automation Module for PLC – HMI Training Kits

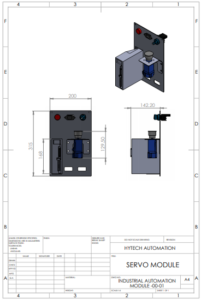

Servo Motor Module

This module consists of a Servo Motor, Servo Drive, Encoder cable and power cable. Servo motor provided is a low inertia motor which runs on 230V AC supply.

This module can also be used as a separate module for Servo motor training.

Generally, this module is mounted on a PLC kit for the ease of use as well as operation.

High speed inputs are required to operate this module which are provided and indicated on PLC o/p module.

What exactly this module provides:

- Exposure to Servo Motor and Drive

- Servo Drive and Servo Motor Connections

- Operation of Servo Motor from PLC and HMI

- Representation of Servo Motor AU in HMI in circular as well as linear mode

Use and interpretation of Servo Motor marking pulse

| Servo Motor Module – BOM | ||

| Description | Qty | Make |

| Servo Motor of minimum capacity 100W and 2000 RPM | 1 | Mitsubishi / Siemens |

| Servo Drive of optimum capacity suitable for the servo motor | 1 | Mitsubishi / Siemens |

| Necessary power cable for Servo Motor | 1 | Mitsubishi / Siemens |

| Necessary encoder for Servo Motor | 1 | Mitsubishi / Siemens |

| Mounting plate in SS 304 for mounting drive and motor | 1 | NA |

| Timer pulley with laser engraving for direction of rotation | 1 | NA |

| Main switch with illuminated indication for switching on the module | 1 | Schneider / Siemens |

| Banana sockets for input connections to PLC | 4 | NA |

| Banana sockets for output connections from PLC | 4 | NA |

| Input Connections from PLC | ||

| These are the signals which are transferred from PLC to Servo motor to initiate its operation. Signals and commands are to be given through a ladder diagram in PLC and the same can be demonstrated / operated from HMI | ||

| 1 | Pulse | |

| 2 | Direction | |

| 3 | Servo ON | |

| 4 | Emergency Stop | |

| 5 | Reset | |

| Output Connections to PLC | ||

| These are the signals which are transferred from Servo Motor to PLC. These commands to be integrated in PLC ladder and / or demonstrated / operated on HMI | ||

| 1 | In Position | |

| 2 | 0 Speed | |

| 3 | Alarm | |