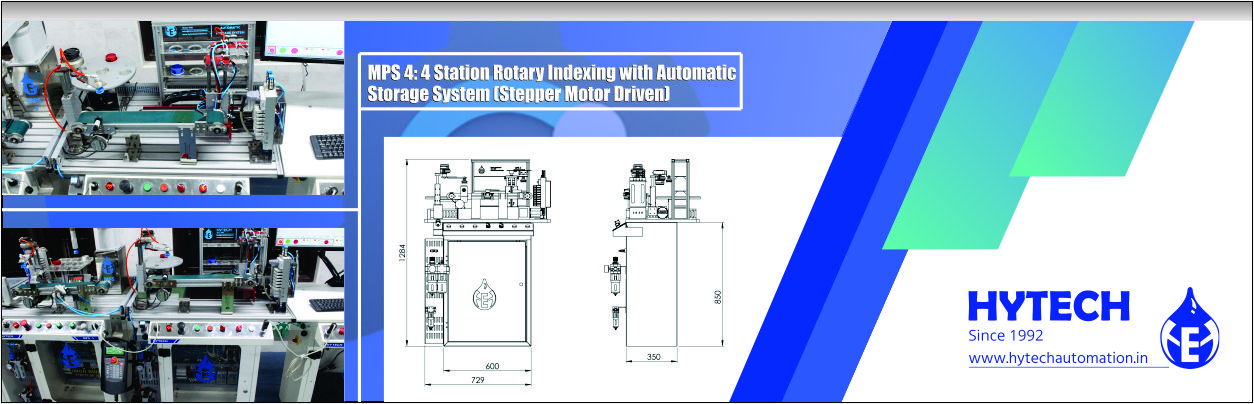

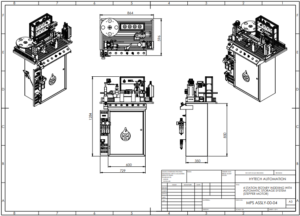

This is ideally a last station in Hytech MPS where job is stored in one of the 8 storage cells. This station is equipped with stepper motors for rotary indexer as well as linear movement of the job loader.

Students can get hands on experience on the operation of stepper motor from PLC and SCADA.

During the startup, referencing of rotary indexing unit as well as the linear transfer station should be carried out. Coordinates of each stepper motor can be displayed on the SCADA.

User has to decide the pallet in which job will be stored.

Bill of Material:

| MPS Station 4: | 4 Station Rotary Indexing with Automatic Storage System (Stepper Motor Driven) |

| Sr No | Description |

| 1 | 4 Station Indexing Mechanism |

| M18 Capacitive sensor for position referencing | |

| Station mounting stand in SS 304 | |

| Stepper motor with stepper drive of suitable capacity | |

| 2 | Pick and Place Arrangement with Vacuum cup |

| Festo Guided Cylinder 20X100 | |

| Festo Vane Motor – DSR-25-180-P | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 3 | Conveyor 70 x 500mm |

| 4 | Automatic Storage System with 8 stations (Pallet with 2 storey, 4 stations on each) |

| 500mm Linear slide with Linear motion guidwways and ball screw | |

| Stepper motor with stepper drive of suitable capacity | |

| M12 Capacitive sensor for position referencing | |

| Pick and Place Arrangement with Vacuum cup | |

| Festo Guided Cylinder 20X100 | |

| Festo Vane Motor – DSR-25-180-P | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 5 | Festo Valve Bank, 10 5/2 DA Solenoid Valves, 1/4 |

| 6 | Festo Pressure Switch |

| 7 | Festo Air Filter |

| 8 | FESTO FRL UNIT |

| 9 | Control Panel with Operation Module |

| 10 | Mounting plate of 22.5 mm thick aluminum extrusions with working dimensions of 820 x 540mm |

| 11 | Siemens S7 1200 PLC (S7 1215C) |

| 12 | HMI Connection Port with SCADA |

| 13 | Control Panel for SCARA |