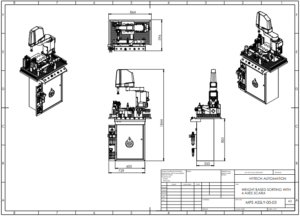

This is ideally a third station in Hytech MPS system which is preceded by MPS 2. Job can be directly transferred from station 2 to station 3.

In case of Multi station option, station 2 places the job in a load cell in MPS 3. The measured weight of the job is displayed on a digital display. Analog output is also provided from an amplifier which can be used to display the weight in SCADA.

Depending on the weight of the job, user can decide to store the job in a particular slot in MPS 3 pallet (total 9 slots are available) or user can transfer the job to MPS 4. Participants are expected to have hands on experience on MPS programming through which they can decide the flow as well as process in each station.

4 axes industrial SCARA robot is used to transfer jobs from conveyor to either pallet or to MPS 4.

In case if the MPS 4 is being used in individual mode, user has to load the job in a load cell pallet to initiate the process. In individual mode, user can use SCARA to store the jobs in SCARA Pallet. MPS 3 is designed particularly to operate efficiently in individual mode to provide hands on experience on SCARA operations which can be termed as SCARA Operation Training as well. Industrial pendant is provided for SCARA operation as well as programming. Software with 3D simulation of SCARA for designing as well as executing various individual SCARA programs is also provided along with a system.

Bill of Material:

| MPS Station 3: | Weight Based Sorting with 4 axes Industrial SCARA Robot |

| Sr No | Description |

| 1 | Stationary Station for job loading from previous station |

| M18 / M12 capacitive sensor connection | |

| 2 | Pick and Place Arrangement with Vacuum cup |

| Festo Guided Cylinder 20X100 | |

| Festo Vane Motor – DSR-25-180-P | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 3 | Conveyor 70 x 500mm |

| 4 | Rotary Rejection Module |

| Festo Vane Motor | |

| Rejection Slide | |

| 5 | Weigh Scale |

| Stationary Station | |

| M18 / M12 capacitive sensor connection | |

| Load Cell | |

| Load Cell Amplifier with Display unit and analog output | |

| 6 | SCARA Robot – 4 Axes |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 7 | Sorting Pallet |

| 8 | Festo Valve Bank, 10 5/2 DA Solenoid Valves, 1/4 |

| 9 | Festo Pressure Switch |

| 10 | Festo Air Filter |

| 11 | FESTO FRL UNIT |

| 12 | Control Panel with Operation Module |

| 13 | Mounting plate of 22.5 mm thick aluminum extrusions with working dimensions of 820 x 540mm |

| 14 | Siemens S7 1200 PLC (S7 1215C) |

| 15 | HMI Connection Port with SCADA |

| 16 | Control Panel for SCARA |

What can be achieved with MPS 3:

- Operation of SCARA Robot

- SCARA Robot operation in individual mode as well as in integration mode with PLC

- Weight based sorting

- Integration of Load cell with PLC and SCADA

- Operation of rotary pick and place station