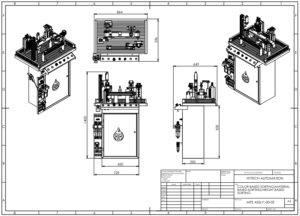

This is ideally a second station in Hytech MPS system which is preceded by MPS 1. Job can be directly transferred from station 1 to station 2.

In case of Multi station option, station 2 starts immediately as the job is transferred from Station 1 to station 2. In case of Individual mode, user has to place the job on the conveyor to initiate the system. In case of multi station mode, job is transferred from station 2 to station 3. In case of individual mode, processed job from station 2 is dropped in a bin to conclude the process.

Digital sensor is provided in station 2 which can be taught to sense a particular color. This input of a digital color sensor can be used to decide the process flow or to display the count on SCADA.

Pneumatic drilling application can actually drill on a raw job of operator’s choice. User can decide the jobs (based on color from MPS2 / material from MPS1) that will be drilled and the ones that will not be drilled.

Bill of Material:

| MPS Station 2: | Color Based Sorting with Pneumatic Drilling Application |

| Sr No | Description |

| 1 | 6 Station Roary Indexing Unit |

| 2 | Sensor Station (Conveyor) with M18 Capacitive and M18 Inductive sensor |

| 3 | Sensor Mounting Bracket (Conveyor) M18 x 2 |

| M18 Capacitive Sensor | |

| M18 Inductive Sensor | |

| 4 | Height Sensing Unit |

| Round Cylinder 12 x 100 | |

| 5 | Pick and Place Arrangement with Vacuum cup |

| Festo Guided Cylinder 20X100 | |

| Festo Vane Motor – DSR-25-180-P | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 6 | Conveyor 70 x 500mm |

| 7 | Color Sensing Assembly |

| Color Sensor Mounting Bracket (Conveyor) | |

| Color Sensor | |

| 8 | Rotary Rejection Module |

| Festo Vane Motor | |

| Rejection Slide | |

| 9 | Stopper Cylinder, Guided |

| 10 | Pick and Place Arrangement with Vacuum cup |

| Festo Guided Cylinder 20X100 | |

| Festo Vane Motor – DSR-25-180-P | |

| Festo VACUUM Generator | |

| Festo Suction Cup | |

| 11 | Festo Valve Bank, 10 5/2 DA Solenoid Valves, 1/4 |

| 12 | Festo Pressure Switch |

| 13 | Festo Air Filter |

| 14 | FESTO FRL UNIT |

| 15 | Control Panel with Operation Module |

| 16 | Mounting plate of 22.5 mm thick aluminum extrusions with working dimensions of 820 x 540mm |

| 17 | Siemens S7 1200 PLC (S7 1215C) |

| 18 | HMI Connection Port with SCADA |

What can be achieved with MPS 2:

- Color based sensing

- Pneumatic Drilling Application

- Acceptance and rejection based on user preference

- Introduction to rotary pick and place unit

- Operation of linear transfer station

- Operation of rod less cylinder