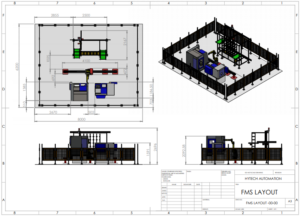

This layout is designed to provide hands on experience on CNC Machines, Completely integrated manufacturing as well as industrial robot. Once this system is installed in any organization / institution, participants can be trained on not only latest CNC / FMS / CIM technology but also on latest industrial robots. That way, there is no need to have a separate lab for robotics training.

This layout consists of following major equipment / software:-

- CNC Turning Center

- CNC Milling (Vertical Machining) Center

- Automatic Storage and Retrieval System with linear transfer station (36 cells)

- Industrial Robot with 6 axes and minimum reach of 1400mm with 10KG payload capacity

- Gantry with Linear motion guideways for robot movement (7th axis) with minimum travel of 5 meter

- Industrial SCADA for communications as well as control of entire system

- 3D Simulation as well as design software (Factory design) with OPC UA connectivity (30 seats)

- Central control station with industrial PLC for entire system connectivity (Industry 4.0 ready)

- Movable Control pendant with touch screen HMI (8 meter)

This layout is designed to make sure that each and every machine / software can be operated either in individual mode or in integration mode. Necessary preventive measures are provided to make sure that there is no risk of accident even when the system is operated by the students / trainee participants.

Participants can change the entire process through SCADA. In case if they want to go back to factory settings, they can install the backup within seconds to make sure that the system is back in original operating condition. This feature gives necessary freedom to participants as well as instructors to try different programming techniques in CIM setup.

Participants can be trainer on following aspects with this (Layout 1) of Computer Integrated Manufacturing System (CIM) / Flexible Manufacturing System (FMS).

- Computer Integrated Manufacturing with SCADA and Industrial 6 axes Robot

- CNC Turning Center Training

- CNC Milling Center Training

- Industrial Robot Training

- SCADA Training

- Factory design and simulation training on 3D software (30 Seats)

What exactly this CIM layout 1 provides:

Basic Level (First / Second year Engineering / Polytechnic Students)

- Hands on experience on CNC Turning Center (Fanuc / Siemens Industrial Controller)

- Hands on experience on CNC Milling Center (Fanuc / Siemens Industrial Controller)

- Hands on Experience on 6 Axes Industrial Robot (Fanuc)

- Pick and Place as well as machine tending applications with 6 axes industrial robot (Fanuc)

- Basic Operation of ‘Automatic Storage and Retrieval System (ASRS)’ with HMI

- Basic Operation of PLC and HMI

- Basic Operation of job loading conveyors with PLC and HMI

Advance Level (Third / Last year Engineering / Polytechnic Students / Research Students)

- Integration of all machines with SCADA system

- Operation of 6 Axes Industrial robot from PLC and SCADA

- Operation of entire CIM / FMS system through PLC – SCADA based automated process

- Design of entire layout and process simulation in 3D software

- OPC UA Connectivity with PLC – SCADA and 3D simulation software

- ASRS cell coordinate settings and integration with SCADA