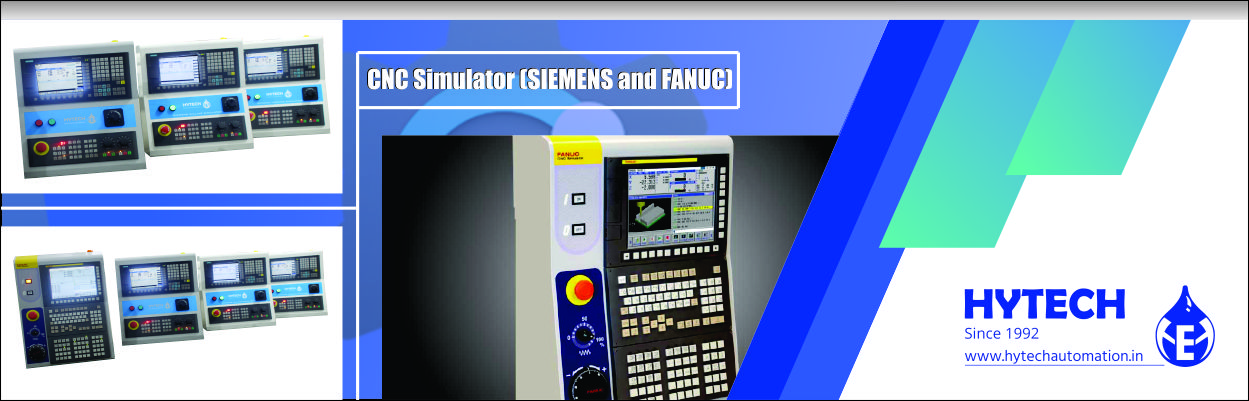

The controller in the simulator is Siemens PPU 151 controller with Siemens MCP and Siemens MPG. Participants can have a hands on experience not only on Siemens PPU but also on MCP s to understand the actual machine operation environment. Tool numbers are displayed on the digital panel on MCP. Each of the simulator is provided along with Siemens PPU + Siemens MPG + Siemens MCP. Participants can not only operate the Siemens CNC controller but they can also vary the basic parameters of the machine such as Software limits, Axes Referencing, Backlash Compensation, etc.

Features of Siemens CNC Simulator:

- 3 axis milling + 1 spindle

- 2 axis turning system + 1 spindle

- 3D simulation and online ladder modificaion

- Inch / metric switchable

- 512kb part program storage, with 400 registered programs

- 32 Tool offset pairs

- Work piece coordinates G52 – G59 + 48 additional on mill

- 4” Color LCD

- Siemens MCP + Siemens MPG

- USB, Flash ATA and Ethernet connectivity

- Optional I/O link I and RS232 serial interface

- Power: AC 100 – 240, 0.8A – 0.4A, 50 – 60Hz

- Power consumption 80w

- Weight: Approx. 26.4lb (12KG)

Downloads